Autonomy Unleashed on Land, Sea, and Air: How drones revolutionize readiness

Speakers

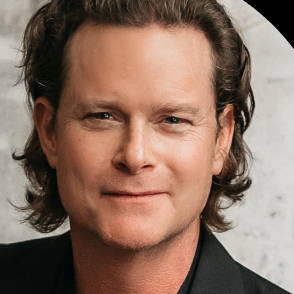

Michael H. Cohen is the CEO of Qii.AI, an AI-enabled asset visualization platform that leverages drone acquired data to enable remote digital inspections. Michael holds a master’s degree in aeronautical sciences from Embry-Riddle Aeronautical University, is a former airline captain (Boeing 737 NG), Chair of Airline Safety (ALPA CJA) and a member of Air Canada’s Emergency Response Team. Michael currently serves as Chair of the Board of Aerial Evolution Association of Canada, a national not-for-profit industry association. Aerial Evolution Association of Canada is committed to promoting public awareness, education and appreciation for the social, economic, and environmental benefits that RPAS systems can provide. Michael is passionate about team building, deep tech, and future aerospace.

Larry Weixel is an Associate Fellow and Principal Artificial Intelligence Architect at Lockheed Martin Aeronautics Company where he has supported nine Aeronautics platforms, including F-16, F-22, F-35, and C-130 for over 25 years. He has built a solid portfolio of innovative solutions and has experience across many domains including software development, data management and analytics, artificial intelligence, aircraft diagnostics, maintainability, wind tunnel testing, production and sustainment operations. He has provided technical leadership for multi-disciplinary teams, resulting in significant efficiency improvements and cost avoidances across the product lifecycle – from development and test to manufacturing and sustainment.

Currently, Larry leads the Lockheed Martin Skunk Works Autonomy/AI Digital Transformation team, where he has developed AI strategies to optimize business operations and improve customer experience through engineering design, production, and sustainment projects. Larry previously led flight test activities for the Prognostics and Health Management team during nearly a decade of service in the F-35 flight test program, which is recognized as one of the most extensive and comprehensive flight test programs in aviation history.

Larry holds a Bachelor’s degree in Mechanical Engineering, a Master’s in Systems Engineering, and has also completed an AI for Business Leaders nanodegree and holds a graduate certificate in cybersecurity. He is an active member of the Baylor University Engineering and Computer Sciences Board of Advocates and has worked with universities and pre-collegiate students to promote STEM education and inspire the next generation of innovators.

“Simplicity is not a sign of incompetence, and complexity is not a sign of intelligence. The ability to make the complex simple for everyone to understand is the ultimate display of mastery.” - Larry A Weixel

Jonathan Montague is a dynamic leader in the aerospace and unmanned system industry, with a strong foundation in various commercial and industrial fields. He holds a BS in Aerospace, Aeronautical and Astronautical Engineering from the University of California, San Diego. Specializing in Solution Engineering, Tech Startup Development, Product Management, and Commercial Drone Operations, Jonathan excels in bringing innovative commercial applications to market. His career spans diverse sectors including film & television, construction, military, and utilities, where he leverages his creative problem-solving and technical implementation skills. Passionate about autonomy, aerospace, and data-driven intelligence, Jonathan combines high-level management with deep technical know-how to drive projects and initiatives to success

Chris Stock is a seasoned professional in program management, systems engineering, and technology innovation. He has a proven track record of leading teams in both the Department of Defense and NASA. Currently, Chris is at the forefront of driving innovation as he leads a technology innovation team that is dedicated to exploring, developing, and experimenting with disruptive and innovative technologies that will shape the future of warfare.

SUMMARY

Skydio and industry experts reveal how autonomous drones are redefining the standards of readiness and maintenance across the most demanding environments— be it sea, air, or land. This session will showcase cutting-edge examples of how the Skydio drone ecosystem, along with partners like Qii.AI and Lockheed Martin, is enhancing the longevity and operational readiness of massive infrastructure, from aircraft and ships to critical land-based equipment. Discover how digital twin technology, combined with advanced inspection, remote operations, and modeling capabilities, reduces manpower and inspection times by up to 90% while simultaneously improving accuracy and safety. We’ll explore the cross-industry applications of this technology, demonstrating its impact not just in large-scale commercial operations, but in base defense, perimeter security, and beyond.

TRANSCRIPT

Good morning, everyone. Michael Cohen. I'm the founder of KeyAI.

I named the company. Everyone calls it QII.

It's a Toronto based ten year old company that, decided through its services journey with drones, to solve the data problem. So about seven years of development.

Right about April twenty twenty, we launched a virtual inspection platform called KeyAI.

We like to focus on artificial intelligence, computer vision largely into two d imagery. We work in three d, but largely two d.

And our focus is corrosion problems, which really sort of coding breakdown through to staining, through to, full blown corrosion. And then we work on concrete problems as well.

We get up these days to work with the Royal Canadian Navy, who's got a, fleet that's really end of life. They're trying to restore it, deploy it very, very quickly, turn it around. And corrosion, of course, they sit on at water at sea, so corrosion is a huge issue. And we've been using Skydio to be able to data acquire the key platform to model and then quantify, literally measure by, square meter, the amount of staining or corrosion on the ship, produce reports, give it to labor, for remediation. And I'm thrilled to be here with this panel and all of you.

Hi, I'm Larry Wexels. I'm the senior manager for artificial intelligence at our Lockheed Martin aeronautics business area.

Responsible for a lot of the strategy and, various different projects that we have. So let me ask by a show of hands, how many of you flew here today?

Maybe not today, this week. Alright. So, how many of you actually went out and did an inspection of the aircraft before you got on the aircraft?

You did? Wow. I knew there'd be one. There had to be one. Alright. So if you think about that, you have a lot of trust in the system that's already there.

And the maintainers that are out there, they're working to try to make sure that these these aircraft are inspected, that every bolt is tightened, every system is checked out. And they're putting their life at risk in a lot of ways, and we'll talk about that in a little bit.

One of the challenges with that is they're they're they're, you know, at high levels, I mean, there are certain aircraft that may be five, six stories in the air, and they're on a cherry picker. So it's a pretty big deal for them to do inspections. And that's not only for the military side, which we're involved in, but also the commercial side of that. So we'll talk a little bit about that today, and, that's kind of what our focus is is doing autonomous aircraft inspections and even beyond that. We'll we'll hit on some of those subjects.

Awesome. And then John Montague is here from our solutions engineering team. For those who of you who have other problems sets for maintenance and and inspection and want a demo and can really see what the drone can do. John's team is out in the field, looking at customer problems and and how Skydio drones can solve those on a day to day basis.

So, John, maybe quick intro from you as well.

So, like, Chris gave me the the intro there. But, I've been in the drone solutions business for about fifteen years, worked at a competitor, the Lockheed for a while as an engineer. But we're starting to see this technology come together, and these workflows that we're gonna talk to today is really tying it together for inspections and ultimately for fleet readiness. So like, Chris said, my team is all over the globe, bringing Skydio assets out there, doing demos, working with, customers to try to understand their problem set and how we can enable them.

And a lot of times it is workflows with partners and and others. And we do just a quick plug, we do have a a multi ship collaborative autonomy demo happening, two thirty to four thirty today. It's gonna be on repeat. So come and see us.

We're it's it's on south side, kinda closer to the big tent from earlier. But, yeah, if you wanna interact with us there, you'll get to see some pretty cool stuff. So yeah.

Alright. Great. Let's jump into it. So we're we're gonna kinda jump into a few use cases. So we're gonna try to shape the problem, current state of affairs, and then what these two gentlemen are doing within their industry teams to to make things more automated, more safe, more predictable, more accessible, and and improve downstream analytics within these spaces. So over to you guys.

Larry?

Alright. So, today, we're gonna we're gonna go through kind of the process that we use at at Lockheed Martin Aeronautics to to do our aircraft inspections.

So there's a lot of benefit from doing this. And, actually, if you go to the next chart, there should be, one more.

Okay. So air, it's our autonomous AI enabled capability. We're using a Skydio drone. We have an ecosystem that that is more than just drone based, but the drone is the predominance right now of what we're using.

Skydio just provides a phenomenal solution to us with its three d scan capability so we can basically go point to an asset that we wanna scan, tell it to go go around and do that scan. It takes all the imagery that we need and it's fed through our artificial intelligence pipeline. We'll walk through that in a minute. But the reason why this is important if you go to the next slide, please.

Aircraft inspections today can be very a very challenging environment. I I don't know if this is a build. It should have had a ring of next slide. There you go.

Okay. Alright. So it can be very time consuming. It's not only from the process of an inspector doing the inspection visually, it's also for the equipment movement.

There's potential, cherry pickers that you may need as you can see here getting to the tail of of aircraft that are six stories in the air. You also have, maintenance stands that are moved around, and there's a lot of infrastructure that comes with doing, asset inspections.

It could also be costly. Again, you've got that support staff, but it's also the equipment that's necessary to do a lot of those inspections.

Inducing damage, one of the big keys there is you're moving maintenance stands around and you're protect potentially running into an aircraft, which happens more often than you think.

And then you also have, walking on the surface of a wing or other surfaces where you're potentially kicking antennas, or other other ass other things on the aircraft surface that, would would cause additional damage.

Hazardous inspectors, and this is a big one. So, you know, I'm aware of many stories of any anywhere from people falling off a wing and winding up in a wheelchair, spinal injuries, broken arms, from falling off of assets. So it's a very big deal in that area. And if we can use a drone rather than have a person doing that initial inspection and to minimize the amount of time they have to do on on those type of assets is very important. Sizable logistics footprint, we've talked about that. So the the cherry pickers and scaffolding and anything like that that's necessary.

Inconsistent outcomes. So if I gave everyone in this in this audience here today, that maintenance task of going to do an inspection, assuming you all had were qualified to do it, you would all still probably come up with a slightly different solution. So this provides consistency that's reliable in how we do in the inspections. And then adverse mission rate impact.

So the whole reason we have aircraft out there, from a military side, obviously, we have missions to perform, is to get those aircraft back in the air as fast as possible. For the commercial side, none of us like sitting at the airport. I felt bad on the way here. The flight next to me, they all were sitting waiting for maintenance to come and do do an inspection.

And actually, it was an inspection they had to do, and apparently they got scrubbed. So lots of issues can come from that and it can impact, not only cost for airlines and and other things there.

So, Larry, real quick. Yeah. Just because this this idea has been around for a while, and I just know what we had to go to to get all the safety approvals to utilize a small drone flying around assets that cost ten to millions tens of millions of dollars, and the damage that could be caused to those expensive assets. So maybe just walk everybody through the process you had to go through, why Skydio was a better solution, and kind of allowed you to get over some of those safety hurdles and approvals to be able to kinda move forward within this space and do this more automated inspection using drones.

Yeah. Absolutely. So the big thing there is well, there's two two primary things that that make Skydio better than any other drone out there in our opinion. So it's the obstacle avoidance capability, phenomenal capability.

We've we've done extensive testing on it and and are are believer of the capability, and then also the three d scan. So we basically are able to fly for a very short period of time, and we're able to take and tell the the drone, go do an autonomous scan. It flies around the air aircraft. We stick the controls in the hands of users when they come out, and, we do demos for them or go out in the field. And they instantly hit the I believe button because of the the the Skydio tech behind it.

Alright. So I'll quickly walk you through the inspection process itself. So, we do the data collection using, again, the the three d scan capability from Skydio. And it right now, I'm talking a lot about air aircraft, but we can go beyond aircraft. So we've been asked to look at dry dock submarines, missiles, the Orion space capsule, various different things. If it needs to be visually inspected, you can use our core engine, our core AI pipeline to do those inspections.

So we we do the scan using Skydio. We take the imagery that's captured and do a reconstruction.

So if you're familiar with photogrammetry, we're basically taking all the imagery that we capture and creating a three d model.

That is then overlaid onto our our, model that we have of the actual aircraft, and we use AI to identify any defects. So whether it's corrosion, paint chips, or different characteristics that can impact our low observable surfaces, stealth, if you will. Those are all included in in how we're doing our assessments there.

Then we characterize them, so we'll tell you various different things about the the the, defect that shows up, the type of defect it is, the size of the defect, and then that's all relayed onto a three-dimensional model that's available to maintainers and can be integrated into a maintenance system. So that's kind of a fast walk through the inspection process.

May I ask you a question?

Sorry.

I didn't pass it. So I think one thing too, because I've worked with you and my team's worked with you a little bit, that I find pretty interesting, on the data collection side. I think, you know, a lot of there's different aircraft obviously and and you're looking at a lot of different aircraft, with this. But like the three d scan setup for those not familiar with three d scan is is very basic and you can be trained in manner of minutes.

I think there's in the future as we're talking a lot of repeatability where you can optimize the the flight path, optimize the look angles, things like that, which, you know, brings us into some of our mission planning capability with with the dock systems you you heard about today. But maybe you can talk a little bit about how three d scan, the the setup, the the flight aspect. I mean, I think it's in my non Skydio drones doing three d scanning missions is is a much more complicated task than I think a lot of people realize. And it that's a good enabler as you mentioned.

Yeah. Absolutely. So, yeah, the three d scan capability makes it very easy for us to basically set a few presets in the in the system, tell it to go scan, and it does what it needs to do. So it we have the the overlap set, the offset from the aircraft that gives us the degree of accuracy we're looking for, the solution, and ultimately, that that path makes it just super easy the way you guys have architected it. So yeah.

I think that's it. Yeah.

Alright. Michael, over to you to talk about ship inspection.

Okay.

I I feel like everything Larry just said, I could probably say about ships.

So maybe I'll speak a little bit more broadly about this. The, the program run-in Canada starts with the federal government.

They've got what they identify as nineteen key industrial capabilities, and two of those capabilities would be RPAS and artificial intelligence. And I'm willing to bet that almost every Western government in terms of their key industrial capabilities have probably identified those.

In the United States, ship based corrosion for your armed forces is about a six billion dollar problem annually, about three hundred ships, which probably puts the US problem of corrosion at the budget of a lot of other nations for their entire military.

Force multiplier now, of course, is deployments critical, to the Middle East and to other areas around the world. So the mission for us is to get to be able to participate in a large group, to be able to turn around the ship at port and get it redeployed as quickly as possible.

And that's a a really, time consuming thing that we're trying to build efficiencies in. So starting with robotics with Skydio makes a lot of sense, and then moving on to AI, of course, makes a lot of sense. We like to say in our shop that AI won't replace you, but someone using AI will replace you. And so we make the pitch that, well, traditional methods would be things like ladders and bows and chairs and notepads and engineers walking around the ship. Could you imagine if someone deployed a drone, grabbed imagery, and from the comfort of their office or even home, were able to do an analysis not in days, but rather in hours and how that would affect labor downstream.

Couple of problems emerge in which, the Skydio platform was really the only solution that we could bring. One, we needed to take engineers that were corrosion analysis engineers and make them pilot. So that's a bit of a journey. They need to get a regulatory approval just like anywhere else.

But they need to be comfortable enough to be able to learn an autonomous system and then fly it.

It's really amazing to me when you get into the defense sector that these are people that operate some of the most sophisticated equipment around the world. They catapult jets. They fire huge guns. They're, you know, top tier in the pyramid of complexity and expertise in mechanicals, but then you show them a, you know, lightweight drone, and they say, absolutely not.

We're not flying that around. I mean, they fly f thirty fives, but put a drone around a ship, and they're, no thanks. So So that's a little bit of a challenge. So the technology has to be incredible to bring on-site.

And then ships, if you can imagine a ship, they are incredibly complex, vehicles.

Guy wires, mass, lots of entry points, exit points, dissimilar surfaces.

So being able to fly around a ship would be an incredibly complex. I I draw analogy to a building facade.

One out of ten ship, nine out of ten in in terms of complexity. So the risk model to take non aviation people, make them aviation people, and then try and image a ship with such resolution that you can perform computer vision on it it requires an incredibly high degree, of autonomy. Then you've got the pier and other things. There's always people around. You've gotta be over top of people. People are on the pier. And so the entire risk profile of the activity, tends to be really quite high.

Yeah. So we're talking physical attributes, but there's a high EMI environment as well. We'll take radars out of the equation because that's a little bit more complicated. So being able to have confidence that your solution's not gonna fall out of the air, have connectivity issues, and high EMI environment as well outside of the complicated physical structures that reside on a ship. I think kinda twofold there, with being able to use the vision the vision navigation in the lead to be able to mitigate any EMI interference and continue to conduct your scan.

Absolutely. You know, I, I'm twenty eight years of my aerospace career, twenty in manned. Now this in in unmanned Manned Aviation has done a marvelous job of learning from errors.

My sense, if you dropped a a drone around a navy vessel, that's probably the end of your program, I think.

Yep. I think that's probably right. Which, you know, higher barrier to entry similar to what we talked about with aircraft inspection, there has to be high confidence for safety approvals to be able to to operate these small drones around equipment while navy vessels even more expensive than most aircraft, which is, I think, why we've we've had success moving into this space where others have not been able to.

Alright. Let me I absolutely agree with that question. Alright.

You wanna move into the rest of your presentation?

Or I didn't know I had a presentation, but Okay.

Here we go.

So we're gonna talk about I really didn't.

They gave me a flight itinerary, and I'm and I'm here now.

So we're Why don't I talk about the process a little bit?

Go ahead.

That'd be great.

Because it's really the at the end of the day, you've gotta work backwards.

So I'm gonna go a little bit onto where our value prop is rather than just the technology. I really see that the, you know, sort of, a to m is a a Skydio product in this, and then the end to zed is is a software platform. And really, what anyone really wants is a report. So what we do is, we consult in a little bit, but the Navy essentially scans their own ships.

What they would like to do is do, pre remediation, that's a diagnostic diagnostic then during labor, which is really quite complicated actually in our space because the amount of material that you purchase for paint, for coating breakdown, for staining and corrosion, if I could invite you into my world, is really quite different. And while you may conceive of of a patch of staining being right beside a patch of corrosion, if the labor crosses over, then we've we've got a problem of budget, we've got a problem of time. So I mean, highly specific areas identified for each problem.

Once we scan it, we bring it in from three d scan into our platform. We use a three d digital twin through photogrammetry like three d scan, allowing the user to click on any part of the ship and then access two d.

And then from two d, we deploy algorithms in that make suggestions. We work a little bit like Grammarly.

So making suggestions on your grammar, we suggest here is a segmented portion of corrosion, we think it's half a meter squared, and then we have a human in the loop Almost everything we do is confirmed by an engineer And then, of course, those results all get quantified, put into a report, and then the report gets segmented, by remediation. So if you wanna produce a report on the helicopter deck that has paint only in certain areas, that would be specified by the exact location, on the ship. They actually divide ships by half meter frames.

And then the remediation of paint, prep paint, and and, and finish is attached to the report, and then that's our business. So that's a workflow from a drone flight right to report. I hope that's helpful.

Yeah. One thing we we talked about before starting the panel is obviously we're we're kind of talking about phase one on how to apply this technology to maintenance and inspection. So that's for ongoing maintenance or predictive maintenance and solving problems here now. I think the other thing that the industry is lacking is just archival information to show degradation over time, that went into current ship design that can be used to, inform future ship design or future aircraft design, whether that's materials, layout methods, paint schemes, corrosion, mitigation techniques, things like that. So I we we see this kinda long term being a phase one approach where we're really trying to solve the time now, ongoing maintenance problem, automate those inspections, and make them, easier and more predictive for for doing predictive maintenance potentially underway for ships in particular, but then also informing future ship or aircraft design to make them more resilient in the future.

Well well, Chris, let me make you you're absolutely right. Let me make the point this way. This is a patrol vessel that's shown on our platform on the left, the three d model on the on the left, and then the users clicked and accessed, the two d imagery on the right.

Prior to this model, the way that the engineers would work would be on a CAD that's held in a PDF. So ships probably I think its manufacture date's about nineteen eighty seven. So all the archives on this ship from the build, one one, the ship builder may not even have given over the CAD, but two, what the engineers today in two thousand twenty four have at their fingertips is a CAD.

So thinking through all this and and were you guys in the leading edge of these, detections off of inspections done with three d scans and other other methodology, tying together a little bit what we heard today with, the X ten for doc and then the on premises solutions that we're bringing for our government customers. Can you describe what you see the vision is for the future, whether it's higher efficiency, whether it's, more remote operations, or with the lack of labor, they're trained and qualified to fly these drones. Maybe it's, in a remote asset or a contract or something like that. And maybe just see how you think next twelve, twenty four, thirty six, or months look like. I'll give it to you first, Larry.

Yeah. So, we are we are looking at the big picture of of, how we can reduce the amount of time that the maintainers are actually spending on the aircraft. And, in our testing, it's looking like we can have at least, depending on the platform, a tenfold reduction in that time, which is, pretty phenomenal and and can really, really, help in the field. From a safety aspect, I mean, there's a lot a lot that can go on there. The autonomy aspect of using docks, I think, is gonna be very important, so we can we're we're wanting to be able to look and say, okay. Go scan this aircraft where we don't have to do all those presets for three d scan and and things, and it goes out and just does it for us. So it was a big picture vision there.

Chris, you had mentioned the historical aspect. Looking back and seeing what an aircraft looked like before, maybe certain maintenance was done on on the aircraft is also very important. Depending on the type of aircraft we're looking at, that could become very important to see where certain restorations have been performed. So there's a lot of lot of that that that I think is is part of the the the, future for what we're doing. Yeah.

Yeah. What about I I guess the other thing, we're hitting on maintenance and inspection, but for retrofits back, Michael, to your point, they might not have a a digital twin or a model of of this particular, asset. So being able to do a scan, then rerender that in CAD and looking at different retrofit, if they're putting on a new weapon system, if they're putting on, additional panels or things like that is or or things we've seen on the ship side. Larry, I don't know if you're seeing that on the aircraft side as well, but because there's not a lot of this information database archived and accessible, to new either civil engineering or new design teams, you know, being able to support the retrofit and upgrade process as well for assets that are a billion dollars plus in value and and really hard to to build and and replace the fleet, is an area where we've seen value add as well.

I think it extends a little bit further. So the I think the the vision here for sure is, once you do it once, you probably can do it every month.

Ships go into enormous amount of damage usage, cruise on and off, those sorts of things. So so the asset is continually it's fairly dynamic in terms of, of the usage and even abuse that it takes. But when it comes into into dock, they'll you know, any restoration literally becomes a construction site.

Scaffolding gets erected on the ship. You've got skyjacks around, material around, those sorts of things. So while you wanna probably get into some sort of routine of change detection so that you've got a diagnostic, then a remediation, then sort of some sort of commissioning so you understand that the work's been properly, performed.

And you can understand that trend over time if you have a baseline, then you've got analytics to show you where you're going.

But I could I see even a a workplace health and safety, factor where particularly today with the drone in the box, where now not only is your information getting over to engineering, but it could get over to health and safety, site planning, those sorts of things, on the pier, because you're now doing repeatable scans. So the force multiplier rolls out to the other divisions, I think. Perfect.

Yeah. John, I don't know if you wanna add anything in terms of what you've heard in the field during demos in terms of other other problems or areas where customers are focused on this. Obviously, ease and use ease ease and usability of the system is is paramount, especially if we're putting this in the hands of sailor sailors who maybe have, you know, three other jobs and this is not their primary duty, making it you know, the ease of use, I think, is is a big factor for being able to really deploy this at scale.

Yeah.

I think sometimes the hardest challenge is getting the systems on on vessels, but, some of the other use cases because this this system is, you know, a tool that can be used in a lot of different ways is, you know, quick battle damage assessment or if, you know, there's a lot of activity right now in various parts of the world. If there's damage to a ship or something, getting an eyes on that as fast as possible, having it as a a part of the safety kit, someone that goes man overboard using this as an ISR platform in that case. But, you know, the same system can do these these different applications.

So I think we're seeing a lot of utility, with our naval customers and others, coast guard, things like that, for those types of, inspections. Even oil oil inspections. We've done some testing recently, using our thermal camera to be able to see different gradations and variations of of oil spills. So there's a lot of extra utility with these systems when you have them in the hands of folks that can utilize them.

And so that the mic and and I would be a a poor solution engineer if I didn't ask this. What's for both of you, what's at least one thing you'd like to see Skydio, do better, an opportunity you see of us to improve our product or or feature you'd like. And we have some engineers and, product in here, so they'll have to listen. So here you go.

So I guess before I before I answer that question, the you mentioned battle damage. And one of the big things with battle damage is sometimes you have chem bio that may be used. So sending, an asset out there, you don't wanna send a human out there if that's if that's the case, immediately at least. And so having a drone be able to do a quick inspection for battle damage is very important.

And also, airfield battle damage. So that's another application, facilities inspections.

These are all areas that we're we're looking at our ourself at Lockheed Martin, but that is that that's some of the the the real deal stuff that I think where drones can can play another really important use case. Now what can we see, in the in the area of what Skydio can improve?

We would love to see well, first of all, the x ten, I think, is bringing a great capability with accuracy.

It's gonna help us have a further standoff away from the aircraft, which means our inspection speeds will increase. So you're answering the mail on that.

The ability to change sensors on the X ten, I think, is gonna is gonna be really important for us. There are certain sensors we're looking at putting on on there, and we'd like to work with you guys on getting, certain sensor sets put on there. So that's that I think is a a critical aspect right now that we're looking at. Excellent. Yeah.

At the risk of repeating, I don't operate.

So but what, for our shop, Jonathan, the ability to get the asset scanned as fast as possible with the highest degree of resolution, is what we wanted at all times. The X ten was, in fact, the X ten has created a really interesting problem for me, because of the resolution.

We ran on a cybersecurity, strategy by which at any passerby in the in the naval shipyard could park their car, look through the, look through the gate and see the ship. So that's the level of of detail that we had with the x two.

Okay.

No notions of privacy. Public can see the ship. With the x ten, now we're reading serial numbers off of life rafts from a hundred feet. So the entire our entire cybersecurity, profile has changed. But as a as a computer vision, company, the highest resolution, possible, if we could if we could double it, great things happen.

Great. You guys wanna open it up to questions in the group to see if if anybody has any questions, kinda more detail on anything?

Sir?

I'll be your mic runner for the day, everybody. Let you go first. Yeah.

Alright. Regarding the military applications, crap. My question just escaped from me.

You know what? That's all my fault. I started yakking at you guys. Who wants to go next? We'll come back to you.

I'll follow on to that. Regarding military applications for, aircraft or ships, can you talk about some of the anomalies that the algorithms would find, get into detail, especially interested in low observable technology?

So I can't go into a lot of details on the low observable technology just because of the forum we're in right now. But I will say that the the general things we would be looking for from an LO perspective, we would be able to detect. If you can visually see it, we can basically train our AI algorithms to do that.

Corrosion, paint issues are big things. Cracks are big things we're looking for right now in in all of our platforms. But the LO arena, there's definitely more secret sauce there. So yeah.

So, Larry, kinda related to that, are there any specific things that human maintainers typically would miss or you would see error error variability across their inspection that you've been able to kinda back out, or or mitigate using using drones.

Sure.

Yeah. So I I'll give you one example. We were, at a base, and we're scanning a k c one thirty five. And we were on the ground for several hours that day, and we did not see a corrosion at the top of the tails, probably about two inches.

The maintenance community wasn't even aware of it. So we were able to use the technology we had to instantly show them what was going on there. And it's because the tail is so high, you really are not able to visually see it that well, especially if you're not focused on looking for that. So that's just one example of how we've been able to use the tech to find something that could be a pretty critical issue.

And then that would that go out as a bulletin to other maintainers to look at that specific spot more closely when they're doing that depending on how how they're doing their operations.

Sure. Yeah. Perfect.

Yeah.

I guess this is a question for for not only the schedule folk, but also for Michael and and Larry.

So from a military's perspective and you mentioned you piqued my interest in, in what you said, Michael, about privacy issue. So to what extent or have you been engaged in developing, designing counter UAS, programs on technologies perhaps? And to what extent have you all considered that from a user perspective?

Well, not at all, sir. It's just not our business.

I'll pass the mic in a second, but I do wanna share for this gentleman that our our challenge we do computer vision and for corrosion.

We had a a navy observer, civilian come on, and he wore his best brown colored sweater that was knit the day he was a visual observer that looked just it was the ugliest sweater I've ever seen. Looks just like corrosion. Like, it's a a sweater designed to fool computer vision. Ships in the background, pure corrosion. Everything else is our challenge. Just focusing on the ship and and, and those things that could look like corrosion for us is is where we focus our science.

Yeah. So I I mean, I can't go into any detail on any counter counter drone type work that we would be doing. Obviously, we're we're large defense contractors. So, there would be some stuff we we could be working on that area. But, I don't know if you guys wanna talk more about how you're avoiding.

Yeah. So Skydio doesn't have a counter system. We're not that's not our business, but we do, with our our Xtendi. And we're we're building resilience into these systems, you know, because counter is the is the reality in a lot of places in the world, and, you know, these systems, you know, be able to operate.

So we know a lot about counter systems and and things, and that's kinda what I can say unless you wanna say more. But No. I think that's fine. Yeah.

Yeah. You wanna counter counter? Correct.

It's a big space.

It's a big space. It's a big space.

Great. Just a question about the end to end inspection process, especially in an environment where you might need multiple platforms. Let's say a ship, you got a drone flying around capturing great data now, but now you got subsea inspection happening perhaps, and there's perhaps nooks and crannies where people are walking around with cameras or visually doing. So how is that world of, like, how is that changing the inspection process? And is it just, like, late fusion of the insights, or is there some sort of three d scan process happening from the get go that can bring everything together no matter what the source was?

Yep. Maybe if you guys could talk about how you segment the scans to get coverage and then maybe if you utilize the AR AR overlays to make sure you have full coverage scan, but kinda how you segment over large scans, especially for vessels in particular.

Well, that's a great question. And and for everyone, I absolutely do not know this gentleman. The our business is just about to go on under the water because that's a missing element for ship inspections. Corrosion happens, foreign species invasion, Contraband actually is a huge issue with ships coming in on the civilian side of things. That's a multibeam sonar and scarioscopic on an ROV, so we think that's the evolution. You've got a drone above the waterline. You've got an ROV below the waterline.

And then I think we're well down a path of probably three sixty camera on the interior. That tech is actually quite easily, is easy and and deployed today. So like Adam showed this morning of sort of an ecosystem to get a holistic data set, I think we're right on the verge of that.

So do you believe these will be, like, three different inspections reports at the end, or you you bring it all together earlier, like, one inspection stage?

So I think it's entirely possible with, an RGB sensor on top, thermal per perhaps if you wanted that, to mate, with millimeter precision, a multibeam or or a stereoscopic, point cloud below the waterline. I think that's entirely possible. And then geosync it with interior would be would be phenomenal.

So and Skydio is right in that ecosystem.

And from our standpoint, we have an an ecosystem of sensors that that we've used. The Skydio is one piece of that equation.

So Skydio can provide certain level of coverage for an aircraft. There are certain areas of the aircraft you just can't get to. So we're we we are our basically, our road map is to use an entire ecosystem to to capture the full digital surface of the aircraft to create a digital surface twin.

Good morning. I'm curious if you either companies have done any studies to look at a side by side comparison of a manual inspection versus the automated inspection and what your level of accuracy between the two of them compares as well as cost time and savings analysis between an automated versus manual. Which one's more accurate? Which one's more cost effective and repeatable?

Yeah. So so for the the aircraft side of the house, we've we're running a pilot in, Marietta, Georgia at our c one thirty production plant. That's what Adam talked about this morning. And, we've done comparisons, and the the accuracy is very similar to a human and sometimes even better than that depending on the defect we're looking for.

So it's absolutely proven itself from that standpoint. The the inspection speed is definitely faster. As I mentioned earlier, it just depends on the use case, the platform we're inspecting, and especially with the x ten being able to pull off a little bit further. We're we're expecting those speeds to increase even more. So, yeah, I mentioned we're we're seeing about a tenfold increase in or decrease in in the inspection speed for some of these use cases.

Yep. I think depending on the customer, though, is it a time savings thing? Is it a readiness, uptime, you know, calibration? So I I think it's I think time savings is part of the component, but readiness and uptime, you know, if we're cutting inspection hours down from four to eight hours per aircraft to under one hour, I think, you know, there is there's a readiness component of it as well.

So, the variables for us would be on on a a ship that we would say something like about a a twenty about a sixteen meter, beam and seventy meters long, so fair sized battleship, Probably in the area of five days to walk it, and we test this all the time with us.

About five hours to do it remotely.

The I'll park, accuracy for a second. You need one good weather window to fly. Actually, probably need a good afternoon weather window to fly. Noon, high high sun.

Whereas walking it, you probably need five good days. You need to transport the people to the ship, of course, because it's highly unlikely. We found that the engineers are generally in urban centers and not, where the ports are. So that whole sort of travel, residence, weather, those sorts of things, and then five days to five hours to inspect. The accuracy, and I'm really surprised to say this as an evangelist for our company, but the accuracy in the field with people with tape measures is horrible.

We can do it much more accurately with, with computer vision, particularly when you're getting into area measurements.

Like, tape measures are just not really, you know, very accurate. They say to us, well, we need millimeter and, well, you've been using a tape measure and a ruler for the last thirty years. No one's marking millimeters with a ruler. So, yeah, we're actually, the the science is pretty strong on on area measurements for for most use cases.

And one thing I'll say was what's different than some other drones. Skydio, obviously, we have our vision system and our obstacle buoyancy, so we can get very close to things. So if you need that sub millimeter even level with the x ten and the sensors, you can get very close to an object and take pictures. Obviously that increases, time on station and whatnot. But that is an advantage in why Skydio can get in these places is because we can get close objects, we're not gonna hit them.

Question up here.

Yeah. You kind of, alluded to my my question around interior captures. And do you guys have a solution? You know, exterior, you have a great workflow on.

But, kind of can you elaborate on, you know, some of the security risk? What what might keep you from doing an interior capture? Is that the reason why you guys don't do interiors to the detail that you do exterior? Is it a security issue, or is it more a feature that's not there inside of your current workflow?

And if you could ask, you know, Scotty over the industry as a whole to create, you know, a sort of workflow or solution or a piece of hardware to attach to, you know, Xtend, for example, what would that look like if you could create a perfect sensor for interior capture?

Well, that's a really good question. I think to get out in front of one part, I think the Skydio would do interiors. It's a matter of what the volume of the interior is.

So if you've got, like, a halo deck or something like that or a large hanger, for instance, with Larry, I think that's entirely Yeah.

It would be entirely possible. The volumetric space plus lighting. Right? It would be both.

Yeah. If you're if you're getting into hallways, it's probably, not the right tool.

I'll pass the mic on this, sir. Our our mission is to be the the best at drone based corrosion analysis, and so we'll leave the interiors to, Sony and others.

But, Larry, because security was that one aspect of that question since you guys have a very sensitive program. Maybe talk about the security apparatus and the type of drone that you're using, you know, its offline state, while you've been able to get approval to use it for the sensitive, programs and assets that you've been inspecting that might that might kinda check the box there as well.

Sure, so, we're currently still using the X2D, which is the defense version. So it has all the right encryption built into it. It's Blue UAS approved.

We know the game is changing a little bit on that right now with some of the customers, but that's really the one of the key things that that also brings us a Skydell US manufactured drone. All that's really important for for the type of missions that we do for national security.

So Yeah.

Maybe to expand on that. So they're conducting the scan. They're setting everything up locally. There's no external connectivity. And then post scan, they're pulling everything, decrypting everything, pulling it off the SD card locally, and it and there's no there's no other transmission, or external transmission beyond that. So they're basically controlling their workflow and information from start a scan to end a scan to post process, you know, without, any kind of compromise in between.

And I could talk a little bit about, the indoor scan. So we do have a mode in our three d scan. It's called indoor scan. It's it's meant to, like, in a volume like this, look out, and you can look in as well. So it really comes down to what size of interior. So obviously airplanes and and ships might be a little small, but, tunnels, bigger bigger interiors, the tent we were in earlier today would be fine for indoor skin and all the same, applications apply. So Yeah.

Just a quick follow-up. I'm in the construction industry, and so we're seeing more and more clients, just adhere some of the ITAR regulations, some of the other government regulations that you typically is reserved for you know, clients like yourselves, but we're seeing that more in the private sector where clients are adopting those types of regulations. So, that was kind of the the point of the the question around security. So thank you.

Are you the clients on their own are enforcing?

Correct. Some of some of our clients that their their data security, you know, we're as building interior exterior. So they're adopting some of the more stringent regulations that, you know, typically reserved for your ships, your your aircraft inspections. But we're seeing that, like, in the data center world and some of the other areas in construction.

So Yeah.

So former helicopter maintainer. So I know how to calibrate a ruler, but how do I calibrate an AI system in my tool shop?

Yeah. So, I mean, the way I I I won't go into a lot of detail on this, but to say that the way we do our models, it allows us to align, the coordinate system. So when we give you a defect, we're telling you an aircraft coordinate. So if youselage station wireline, buttline coordinates.

We're also telling you the size of the the defect. So all of our models have that built into it. It relays that onto a three-dimensional model where you can actually pull that up. You pull up the three d model, it can mouse around it, and then point to the defect that it's showing, and it'll pull up that two dimensional picture that it took.

And you could see what what the dimensions of that particular defect were in in aircraft coordinates.

We do a couple of things.

We have known, specs on on the ship, so we test against that. Of course, algorithm runs confidence levels, so each segmentation, would run a a confidence level, but mostly real world testing. So the moment that we have a known fixed thing, then we can test it against what the actual measurement is. But the thing, and it's a clever question, the the answer really exists in the tolerance that the client requires because there will be an error.

So if your tolerance if your tolerance is one foot, you're happy with that, great. We did roofing for years. Those guys cut out five feet by they they'll draw a line, they'll cut two feet over from it.

If you're in the centimeter range and you're within less than ten percent, generally, I my experience in been fairly comfortable with that because the historicals have been zero.

Thank you.

Any other questions?

Alright. I think I think we're it between you and lunch. So appreciate everybody attending.

If you take away anything, you saw a lot of utility inspection use cases today. We think the surface space is just as big in the government market for asset inspection, building inspection, critical infrastructure inspection, and we want to partner, with you to solve those problems. So appreciate your time. Thanks, everybody.